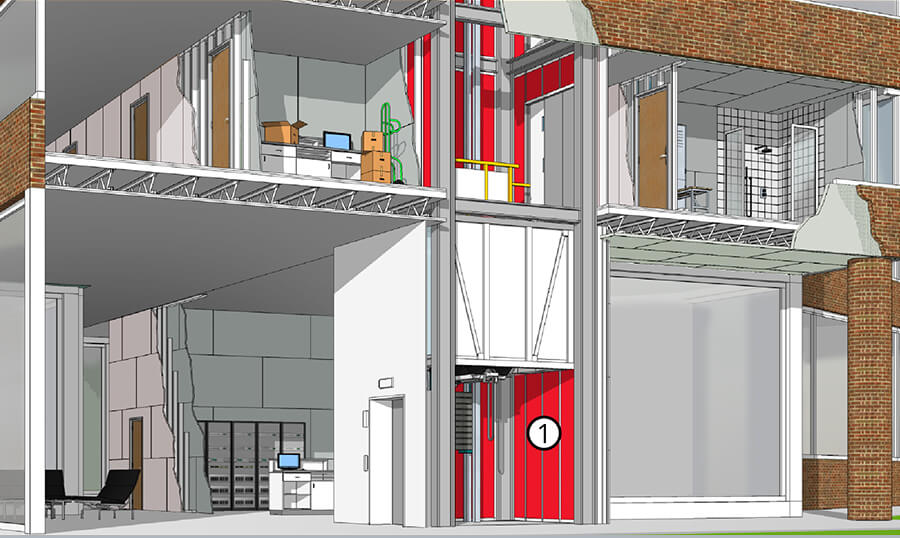

One of our current projects is a change of occupancy where the change will require a 2 hour rating between the main level a 2 occupancy and the r 2 occupancy above.

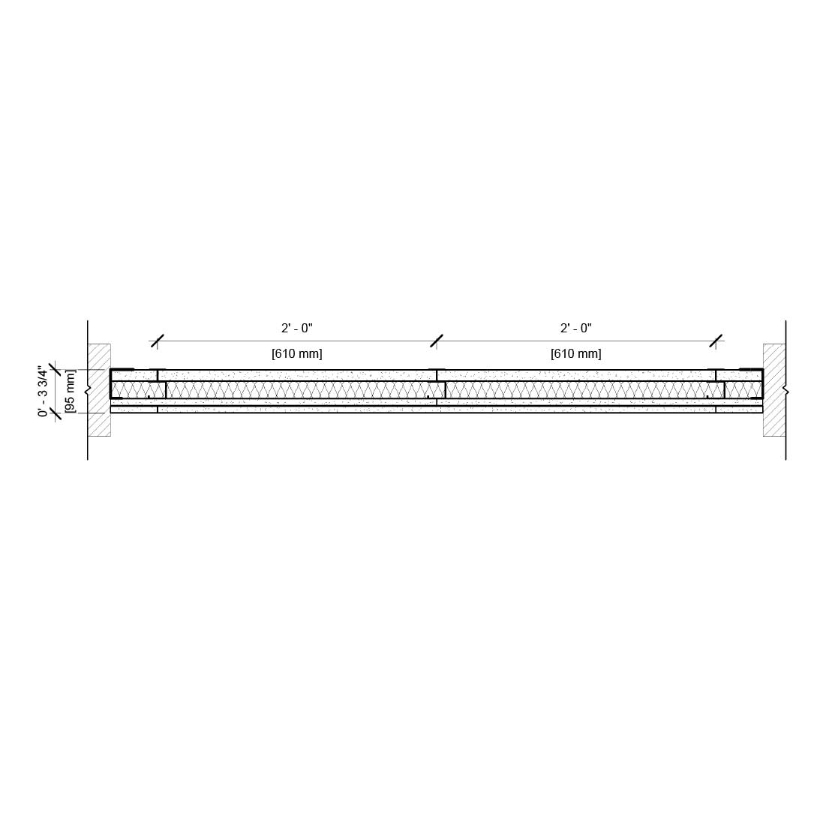

2 hr shaft liner detail between floors.

This is true for walls separating shafts when there is only a structural beam provided for supporting the wall.

Minimum 8 x 8 maximum 48 x 48.

Once the typical wall assembly for the shaft has been selected the detail at the floor to shaft intersection should be addressed.

The challenge in these situations is that you do not want to tear into the floor or change out the floor framing members.

Shaft wall ceiling membrane the two hour horizontal membrane also used in two hour duct enclosures and the membranes used.

2 hour wall with shaftliner.

Shaft enclosures are required to have a fi re resistance rating of not less than 2 hours when connecting four or more stories.

A fi re resistance rating of not less than 1 hour is required for shaft enclosures connecting less than four stories.

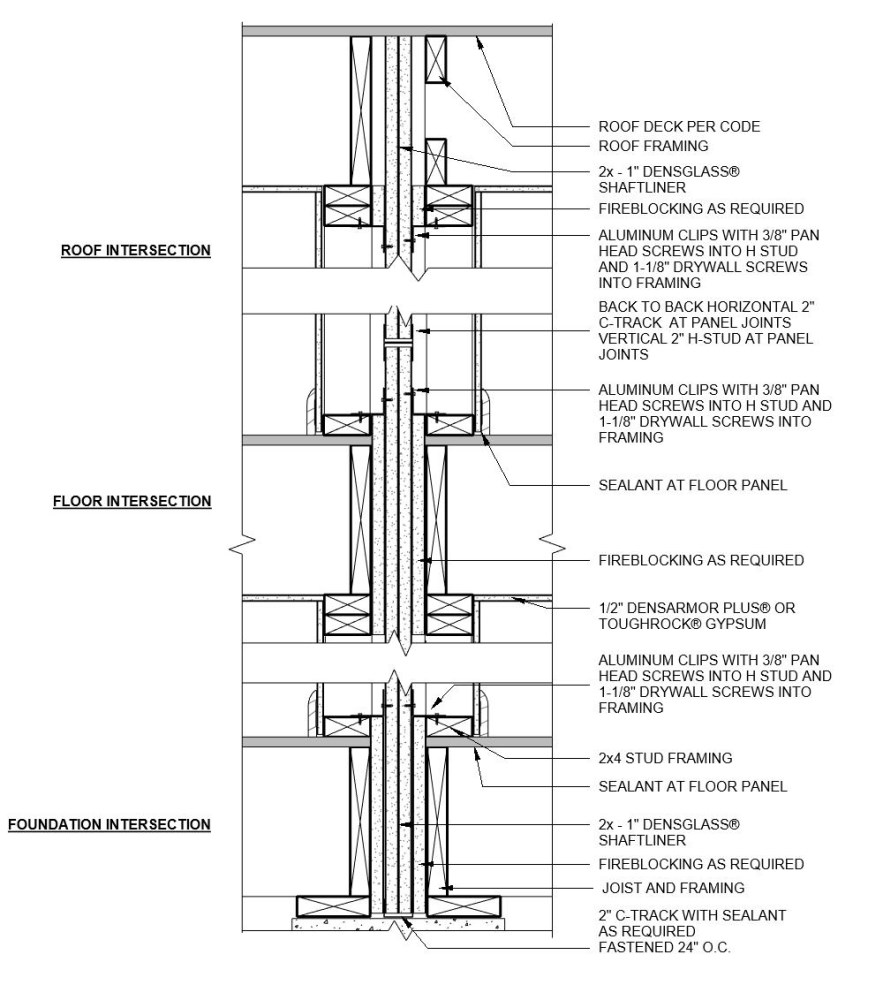

The system is stacked floor to floor allowing progressive construction using the breakaway aluminum clips.

Attach j track to the floor with fasteners spaced at 24 o c.

16 gauge steel with a 1 flange.

Sometimes make it difficult to install shaft liner panels and studs vertically.

See model fd2 for lengths greater than.

The system consists of 2 wide light gauge metal h studs which secure two layers of 1 m glass shaft liner 1 m bloc shaft liner or 1 traditional shaft liner panels vertically between adjacent stud walls.

Secure each piece with the appropriate power driven fasteners spaced a maximum 24 o c.

The look of this detail will depend on the floor framing type and bearing condition.

Install proroc shaftliner type x boards vertically.

2 thick insulated 20 gauge steel with continuous hinge.

Install j track along the ceiling line and vertically at columns and abutting partitions positioning the long legs closest to the shaft.

Often misunderstood by designers is the difference between.